Linear actuators, including belt-driven, ball screw-driven, and lead screw-driven models, designed for automation, medical, and industrial applications, offering load capacities up to 83,400 N (18,750 lb) and stroke lengths up to 6,000 mm (236 in). They feature customizable carriage movement with the following options:

- Gliding Surface Technology™ with self-lubricating FrelonGOLD® PTFE liners for smooth, maintenance-free gliding

- Plain linear pillow blocks on rail-supported shafts for robust support

- Ball bearing profile rails for superior stability and precision

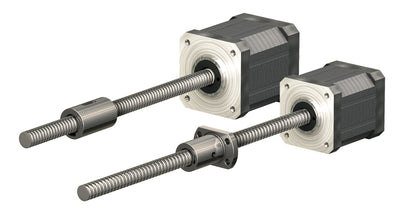

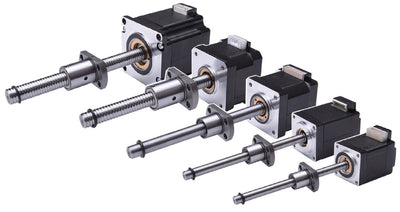

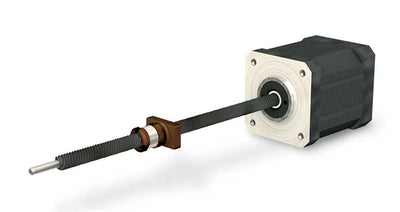

Equipped with integrated NEMA motors, motor mounts, or blank base plates, they include various nut types (standard, anti-backlash, preloaded), hand brakes, and screw diameters for optimized performance. Belt-driven actuators deliver high speeds and long strokes for low-maintenance, contamination-resistant applications but offer lower precision and load capacity. Ball screw-driven actuators provide high stiffness and precision for heavy, cantilevered loads, with preloaded nuts and multiple accuracy classes, requiring clean environments and periodic lubrication. Lead screw-driven actuators ensure precise, quiet operation with vibration damping and self-lubricating or anti-backlash nuts, ideal for lower loads and slower speeds. Constructed with durable linear rails, shafts, carriages, and bearings, these actuators are size-interchangeable and built for reliability in demanding conditions.