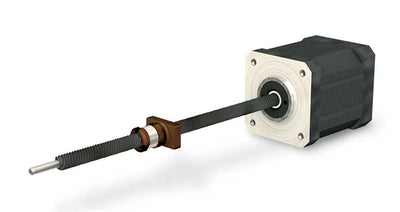

Lead Screw Linear Actuator Assemblies with NEMA Motors

High-Precision with Anti-Backlash Technology

Non-captive Lead Screw Assembly – NEMA 11

| Name | Diameter (in) | Lead (in) | Length (in) | Motor | Shop Link |

|---|---|---|---|---|---|

| LSR18005T-08.00-NCF111-NNN-NNN | 0.188 | 0.050 | 8 | NEMA 11 | Shop Now |

| LSR18050T-08.00-NCF111-NNN-NNN | 0.188 | 0.500 | 8 | NEMA 11 | Shop Now |

Non-captive Lead Screw Assembly – NEMA 14

| Name | Diameter (mm) | Lead (mm) | Length (mm) | Motor | Shop Link |

|---|---|---|---|---|---|

| LSR0601T-0200-NCF141-NNN-NNN | 6 | 1 | 200 | NEMA 14 | Shop Now |

| LSR0602T-0200-NCF141-NNN-NNN | 6 | 2 | 200 | NEMA 14 | Shop Now |

| LSR0605T-0200-NCF141-NNN-NNN | 6 | 5 | 200 | NEMA 14 | Shop Now |

Non-captive Lead Screw Assembly – NEMA 17

| Name | Diameter (mm) | Lead (mm) | Length (mm) | Motor | Shop Link |

|---|---|---|---|---|---|

| LSR0601T-0250-NCF171-NNN-NNN | 6 | 1 | 250 | NEMA 17 | Shop Now |

| LSR0602T-0250-NCF171-NNN-NNN | 6 | 2 | 250 | NEMA 17 | Shop Now |

| LSR0605T-0250-NCF171-NNN-NNN | 6 | 5 | 250 | NEMA 17 | Shop Now |

Non-captive Lead Screw Assembly – NEMA 23

| Name | Diameter (mm) | Lead (mm) | Length (mm) | Motor | Shop Link |

|---|---|---|---|---|---|

| LSR1001T-0300-NCF231-NNN-NNN | 10 | 1 | 300 | NEMA 23 | Shop Now |

| LSR1005T-0300-NCF231-NNN-NNN | 10 | 5 | 300 | NEMA 23 | Shop Now |

| LSR1010T-0300-NCF231-NNN-NNN | 10 | 10 | 300 | NEMA 23 | Shop Now |

Lead Screw Assembly - NEMA 8 with RCF

| Name | Diameter (mm) | Lead (mm) | Length (mm) | Motor | Shop Link |

|---|---|---|---|---|---|

| LSR0601T-0100-RCF-080-NNN-N | 6 | 1 | 100 | NEMA 8 | Shop Now |

Lead Screw Assembly - NEMA 8 with VCF

| Name | Diameter (mm) | Lead (mm) | Length (mm) | Motor | Shop Link |

|---|---|---|---|---|---|

| LSR0601T-0200-VCF-080-NNN-N | 6 | 1 | 200 | NEMA 8 | Shop Now |

| LSR0605T-0250-VCF-080-NNN-N | 6 | 5 | 250 | NEMA 8 | Shop Now |

Lead Screw Assembly - NEMA 11 with VCF

| Name | Diameter (mm) | Lead (mm) | Length (mm) | Motor | Shop Link |

|---|---|---|---|---|---|

| LSR0601T-0100-VCF-111-NNN-N | 6 | 1 | 100 | NEMA 11 | Shop Now |

| LSR0605T-0250-VCF-111-NNN-N | 6 | 5 | 250 | NEMA 11 | Shop Now |

| LSR0605T-0300-VCF-111-NNN-N | 6 | 5 | 300 | NEMA 11 | Shop Now |

Lead Screw Assembly - NEMA 14 with RCF

| Name | Diameter (mm) | Lead (mm) | Length (mm) | Motor | Shop Link |

|---|---|---|---|---|---|

| LSR1005T-0200-RCF-140-NNN-N | 10 | 5 | 200 | NEMA 14 | Shop Now |

Lead Screw Assembly - NEMA 14 with TCF

| Name | Diameter (mm) | Lead (mm) | Length (mm) | Motor | Shop Link |

|---|---|---|---|---|---|

| LSR1001T-0300-TCF-140-NNN-N | 10 | 1 | 300 | NEMA 14 | Shop Now |

| LSR1005T-0400-TCF-140-NNN-N | 10 | 5 | 400 | NEMA 14 | Shop Now |

Lead Screw Assembly - NEMA 17 with RCF

| Name | Diameter (mm) | Lead (mm) | Length (mm) | Motor | Shop Link |

|---|---|---|---|---|---|

| LSR1201T-0300-RCF-171-NNN-N | 12 | 1 | 300 | NEMA 17 | Shop Now |

| LSR1205T-0400-RCF-171-NNN-N | 12 | 5 | 400 | NEMA 17 | Shop Now |

| LSR1205T-0500-RCF-172-NNN-N | 12 | 5 | 500 | NEMA 17 | Shop Now |

Lead Screw Assembly - NEMA 23 with RCF

| Name | Diameter (mm) | Lead (mm) | Length (mm) | Motor | Shop Link |

|---|---|---|---|---|---|

| LSR1601T-0300-RCF-231-NNN-N | 16 | 1 | 300 | NEMA 23 | Shop Now |

| LSR1605T-0400-RCF-232-NNN-N | 16 | 5 | 400 | NEMA 23 | Shop Now |

| LSR1605T-0500-RCF-231-NNN-N | 16 | 5 | 500 | NEMA 23 | Shop Now |