Linear actuators are linear guide systems with a mechanical drive and configurable power source, including electric motors or manual inputs such as a hand crank, that produce precise, controlled straight-line motion. Available in belt-driven, ball screw-driven, and lead screw-driven designs, these products are used across automation, medical, and industrial applications, supporting loads up to 83,400 N (18,750 lb) and stroke lengths up to 6,000 mm (236 in).

Carriage motion can be configured to match application requirements using multiple guidance options. Gliding Surface Technology™ with self-lubricating FrelonGOLD® PTFE liners provides smooth, quiet, and maintenance-free operation. Plain linear pillow blocks on rail-supported shafts offer robust structural support, while ball bearing profile rails deliver high stiffness and stability for applications with cantilevered loads or higher moments.

NEMA motors, motor mounts for customer-supplied motors, or blank base plates are available to support both automated and manual operation. Manual configurations support hand brakes or cranks, while motor-driven systems integrate easily with standard motion control architectures. A range of screw diameters, lead sizes, and nut types are offered, including standard, anti-backlash, and preloaded nuts, allowing performance to be tuned for speed, force, efficiency, and repeatability.

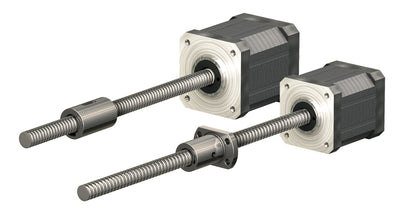

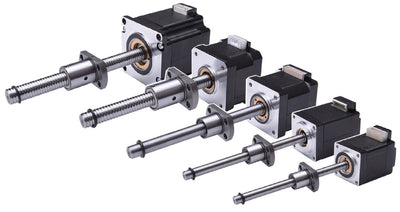

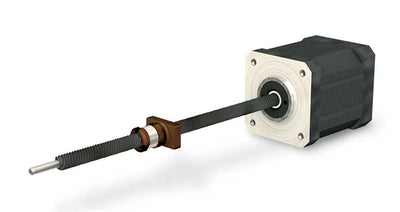

Belt-driven actuators are well suited for long strokes and higher travel speeds with low maintenance requirements, particularly in environments where contamination resistance is important and positioning accuracy is moderate. Ball screw-driven actuators provide high stiffness, precision, and load capacity, making them appropriate for heavier and cantilevered loads, though they require clean operating conditions and periodic lubrication. Lead screw-driven actuators offer a cost-effective solution for precise, quiet motion, with inherent vibration damping and self-lubricating or anti-backlash nut options for lower-load, lower-speed applications.

Built with durable rails, shafts, carriages, and bearings, these linear motion systems are size-interchangeable across configurations to simplify design changes and future upgrades, delivering reliable performance and predictable service life in demanding conditions.