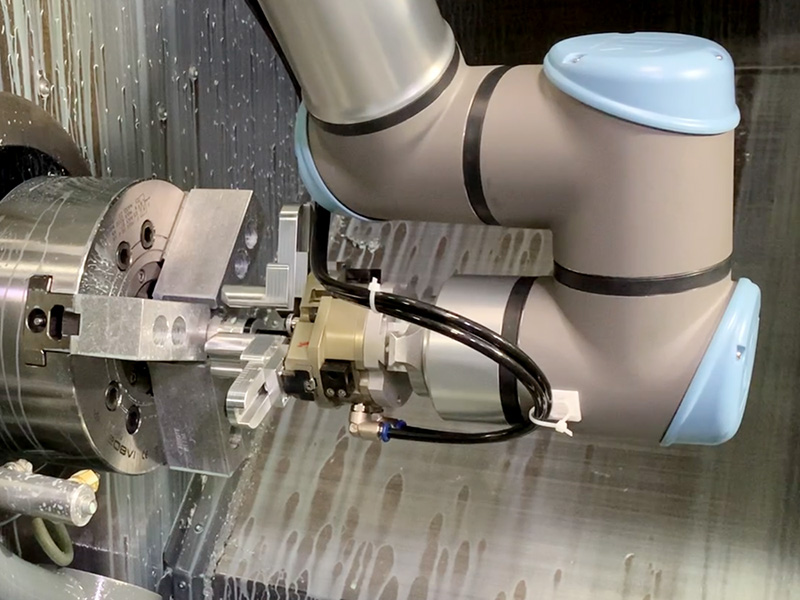

PBC Linear showed the Cobot Feeder along with other tools and linear motion components that are helping to drive manufacturing automation forward. The Cobot Feeder was live at the the UR Cobots booth. Visitors saw the Cobot Feeder and UR cobots working together to drive manufacturing productivity to the next level.

Cobot Feeder/CNC Machine

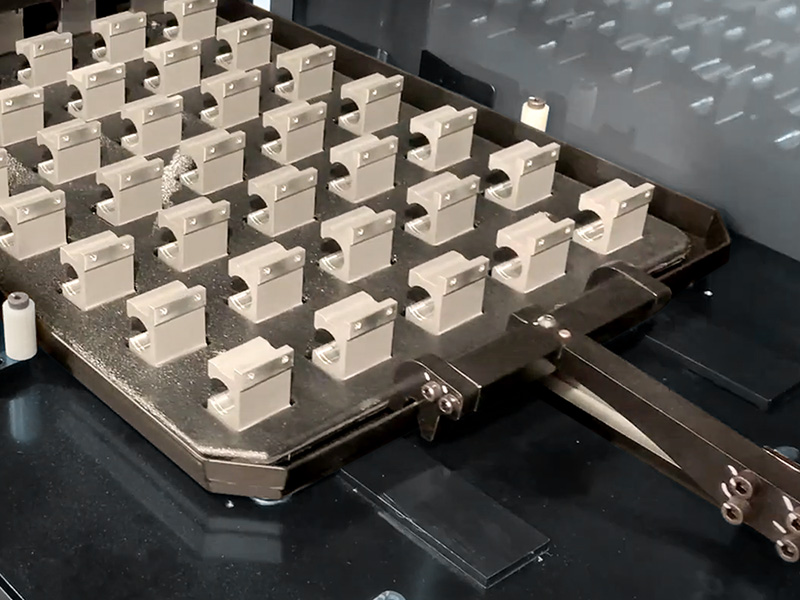

Cobot Feeder/Parts trays

Cobot pick and place

CNC Machining

The main focus at the PBC Linear booth was our Cobot Feeder, which offers an automation solutions for a variety of manufacturing applications especially in the area of high-mix, high-volume production.

Automation processes: machine tending, part loading & unloading, assembly operations, cleaning & deburring stations, grinding & polishing, laser marking, palletizing, and more.

Our Cobot Feeder is designed to boost cobot production without significant increases in labor. This versatile tool provides a standardized platform for storing, staging, and delivering parts trays into a position where they can be consistently loaded and unloaded via a cobot device. Enthusiasm and interest in the Cobot Feeder is soaring now that we have received Universal Robots+ (UR+) partner certification. The Cobot Feeder, in tandem with Universal Robots (UR), looks to solve material handling and labor shortage issues while achieving a higher return on investment.