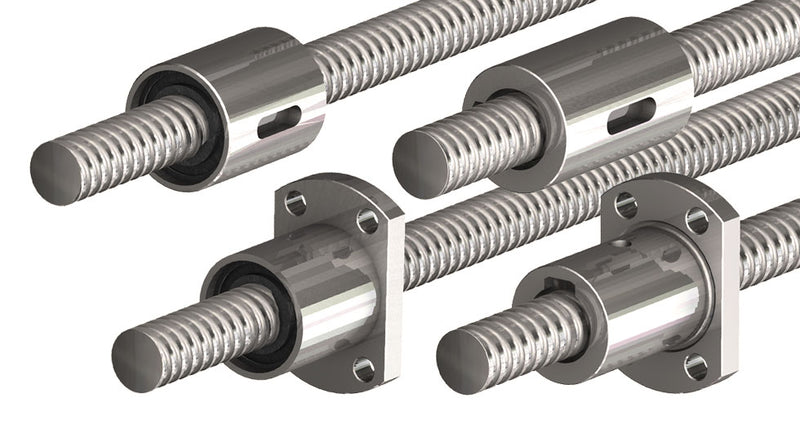

Lead Screws and Ball Screws

Lead Screws and Ball Screws both convert rotational motion into linear movement. The main difference between lead screws and ball screws is that ball screws rely on ball bearings to minimize friction and convert motion, while lead screws rely on low coefficients of friction between materials. When deciding between lead screws and ball screws, the choice largely depends on the specific requirements of the project. Use the chart and detailed information below to help decide on which product line is best suited for your application.

| Feature | Lead Screw | Ball Screw |

|---|---|---|

| Low Cost | X | |

| High Speeds | X | |

| High Loads | X | |

| Quiet Motion | X | |

| Self-Lubricating (Reduced Maintenance) | X | |

| High Accuracy | X | |

| Anti-Backlash Nut Options | X | |

| High Efficiency (Require less torque) | X |

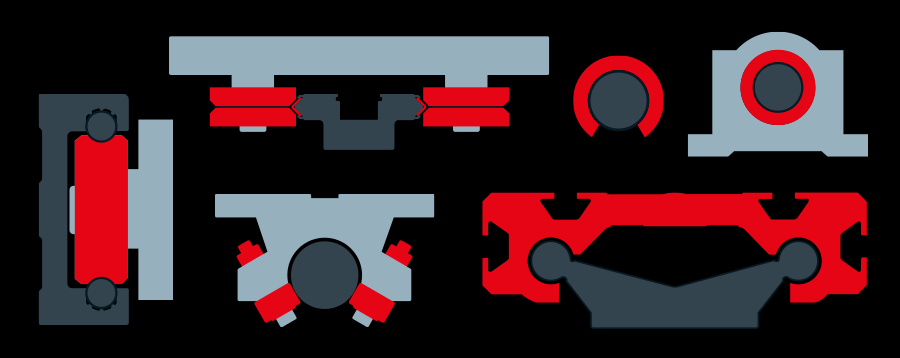

Gliding Surface Technology Linear Rail Family

Explore the versatile world of linear motion with the GST family, where precision engineering meets industry-specific needs

- Uni-Guide Linear Slide: At the heart of our lineup is the Uni-Guide Linear Slide System, a pinnacle of reliability and innovation offered in tall and low profiles. Utilizing Simplicity technology in a two-piece aluminum design, it eliminates tolerance stack-up, dampens vibrations, and handles shock loads effortlessly. With a static load capacity of up to 1,000 lb and a lightweight, pre-engineered assembly, it's the go-to choice for applications demanding precision and durability.

- Mini-Rail Linear Slide: For miniature applications requiring top-notch performance, the Mini-Rail Miniature Linear Slide shines. Its two-piece design, fast installation, and static load capacity of up to 3,559 N make it a trusted choice for semiconductor wafer handling and other demanding tasks.

- Low Profile Mini-Rail Linear Slide: Looking for compact, low-friction motion? Enter the Low Profile Mini-Rail Linear Slide. Ideal for space-constrained environments in industries like medical and packaging, its molded polymer slider with stainless steel thread inserts and anodized aluminum rails ensure smooth operation and chemical resistance.

Cam Roller Technology Linear Rail Family

- Commercial Rail Linear Slide: Featuring precision-formed zinc-plated carbon steel linear rails and machined aluminum slider bodies, the Commercial Rail Linear Slide is designed for applications such as automation, packaging, and material handling. With transfer speeds up to 1.5 m/s and load capability up to 1,330 N, it offers flexibility and durability.

- Hevi-Rail Roller Bearings: The Hevi-Rail series provides solutions for extreme high load capacities and industrial strength handling applications. With options like fixed or adjustable bearings and linear guide rail lengths up to 6 m, Hevi-Rail is suitable for custom lift units, lift trucks, and heavy load applications in industries such as material handling, depalletizers, aerospace and steel.

- Hardened Crown Roller Bearings: PAC Hardened Crown Rollers come pre-assembled and self-aligning, making them a low-cost linear motion solution for point-to-point applications. With maximum wheel bearing load up to 1,334 N and transfer speeds up to 762 mm/s, they are suitable for machine tool doors, guarding, and material transfer.

- Redi-Rail Linear Slide: Available in metric and inch versions, Redi-Rail Linear Slides feature precision machined aluminum linear slide rails with hardened steel races, offering high accuracy and parallelism. With options for corrosion resistance and compact designs, they are suitable for applications such as automated vending and medical or laboratory equipment.

- V-Guide: The V-Guide offers flexibility with V-Guide wheels and bushings available in various sizes and materials such as stainless steel. With radial loads up to 9.9 N per wheel and options for shielded or sealed bearings, V-Guide wheels and bushings provide precise and reliable linear motion for diverse mounting configurations.

Integral-V Technology Linear Rail Family

The IVT family of v-rail linear guides encompasses a diverse array of linear slides meticulously crafted to meet the exacting demands of industrial applications. Crafted from precision-machined aluminum anodized linear slide rails featuring embedded hardened stainless-steel races, IVT linear slides offer a unique blend of lightweight construction and robust performance.

With options like wider base rails for enhanced stability and alternative cost-effective solutions tailored to various needs, the IVT family ensures versatility across industries. With load capacities of up to 8,900 N (2,000 lbf) and high-speed capacities reaching 10 m/s (394 in/s), these linear guide rails excel in dynamic environments.

Furthermore, their maintenance-free operation and compatibility with a wide range of accessories—including wheel covers, scrapers, and wipers—make them ideal for applications spanning automation, packaging, semiconductor handling, and more. Whether you require long-length applications, rapid speed capabilities, or resilience to harsh conditions, the IVT family offers tailored solutions to elevate your linear motion systems to new heights of performance and reliability.