Linear Motion Innovation Through the Years

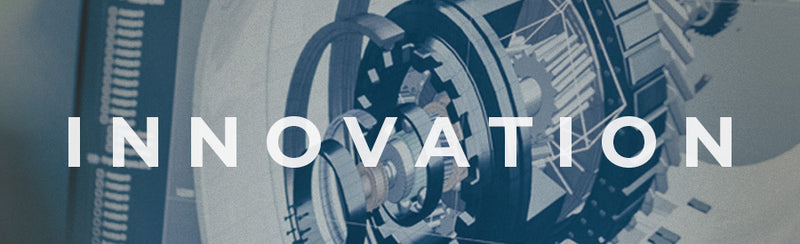

The story of PBC Linear begins with an innovative solution to a common issue of catastrophic failure with linear ball bearings. The result was the creation and eventual patent for our iconic red Simplicity bearing. During the last four decades, that successful plain bearing design has spurred innovation and a substantial portfolio of linear motion products and automation processes that help simplify customer applications and reduce costs. In fact, fifty percent of our yearly revenue can be attributed to products that are designated as either proprietary or that we currently hold patents on.

Simplicity Plain Linear Bearing Design: Utilizes a bonded Frelon liner that provides flexibility across diverse applications and extreme conditions including temperature, vibration, washdown, and particulates.

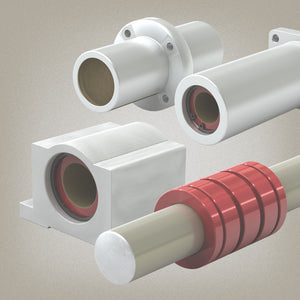

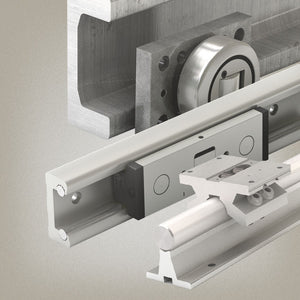

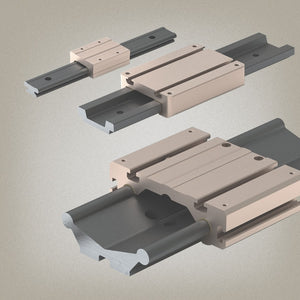

Integral-V™ Linear Guides: Versatile v-rail and v-wheel guide systems for vigorous applications and dirty environments. Two-piece v-groove system eliminates mounting components that are typical in profile rail, slashing assembly time.

SIMO® (Simultaneous Integral Milling Operation): Patented process uses synchronized cutters to eliminate extrusion variances, ensuring tight tolerances and repeatable surfaces in linear guides and actuators.

Large format 3D printers: 3D printer product line provides large build volume and fast print rates for industries and institutions wanting to create quicker, cheaper prototypes and custom parts processing.

Anti-backlash nut: Patented lead screw nut provides 2-4 times superior performance verses conventional coil springs, over 2 times superior backlash compensation, and consistent pre-load over the life of the screw.

Cobot Feeder: An automation tool that enhances cobot production by consistently loading and unloading material parts trays, eliminating the need to manually replace them - making cobots, operators, and factory operations better.

Linear Motion Solutions

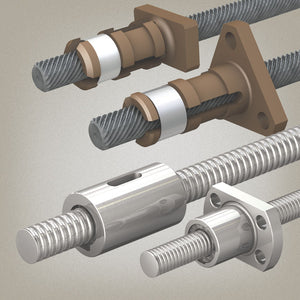

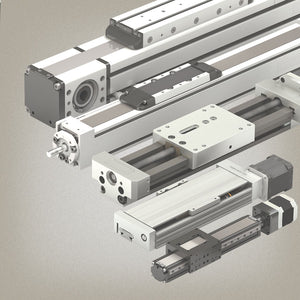

The self-lubricating plain linear bearings, including pillow blocks and linear slides, quickly gained popularity in our first decade of production, all featuring our innovative maintenance-free Frelon® liner technology. As PBC Linear has grown, we have continued to refine and expand our offerings in response to customer application demands, introducing ball and roller type bearings, screw-driven assemblies, linear actuators, and optimized shafting.

Plain-type linear bearings including inch and metric versions of pillow blocks, flange mounts, and sleeves, in round and square shaft options.

Linear Ball-type bearings including inch and metric versions of pillow blocks and flange bearings, and metric compact thin wall ball bearings.

Roller bearings include track roller types like Commercial Rail, Redi-Rail, Hevi-Rail, and IVT V-Rail, along with Roller Pillow Blocks for round shafts.

Plain-type 2-piece gliding surface technology utilizes Frelon self-lubricating liners and includes low profile linear guies and tall profile Uni-Guides, standard and low profile Mini-Rail, and screw driven Uni-Guides.

Screw-driven technology including Lead Screws with Constant Force™ technology nuts, and miniature metric Ball Screws.

Linear Actuators including a full range of linear actuators with best-fit options for size, speed, drive type, lineaer motion mechanism and power sources.

Service

The culture at PBC Linear is a blend of midwestern work ethic paired with skilled technicians, knowledgeable service personnel, and a multi-disciplined group of trained engineers – not to mention a dog-friendly office. Together, they form a full-service team that creates long-lasting and cost-efficient linear motion solutions for a variety of worldwide industries. For PBC Linear, customer satisfaction can be measured in repeat business and successful OEM solutions.

We retain a high level of customer satisfaction through:

- Wide range of products to fit application demands

- Shorter lead times that get machines quickly into production

- Thorough communication that keeps customers informed

- Expert engineering guidance to provide the best solutions

- Comprehensive testing for high quality parts

Growth

What began as a small bearing shop has expanded to include new business entities that offer a broader reach. We are now one of the largest privately-held linear motion product manufacturers in the United States. Our expanded reach applies to not only North America, but includes the shipment of products to over one hundred countries.

As PBC Linear continues its upward growth trajectory, we are evolving from a standard product manufacturing company into a technology OEM company. Within this role, we provide customers with products that are consistent with their OEM designs. Those products include not only linear motion components, but also prototyping and automation tools. This vertically integrated model allows PBC Linear to be an essential part of innovation across industries, bringing prosperity to both producer and user.

1983 Pacific Bearing Company is founded by CEO Robert Schroeder.

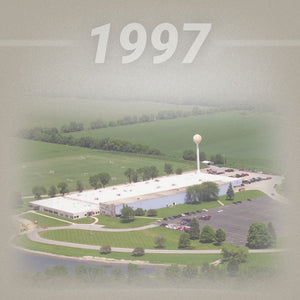

1997 PBC Linear headquarters relocated to 150,000 ft² facility in Roscoe, IL.

2008 PBC Lineartechnik GmbH established to meet European needs.

2008 Pacific Bearing Co. d.b.a. PBC Linear to represent actuator offerings.

2011 Major manufacturing expansion of an additional FMS machine.

2011 AS9100C certification achieved for aerospace and defense industries.

2013 PBC Linear acquires LEE Controls LLC.

2014 3D Platform founded to provide large format 3D printers.

2015 PBC + Moons’ Motors joint venture founded.

2019 PBC expands 66,000 ft² with new building at their main US location.

2020 Applied Cobotics brand created to bring cobots (robots), cobot feeders, and Augemented Reality (VR) training onto the factory floor.

2023 $5 million Flexible Manufacturing System (FMS) installed.

Innovation into the Future!

As a leader in linear motion technologies, our manufacturing facility continues to grow and evolve, dedicated to providing expanding markets with effective products and services. This commitment reinforces the PBC Linear brand as a trusted source for innovative linear motion products and automation success. Our large-scale investments position us well for the future of Manufacturing 4.0, including our new Flexible Manufacturing System (FMS), which is now fully operational.

To all our partners who have been part of this journey, we say “Thank you, and we look forward to continuing our collaboration in the future!”

- Choosing a selection results in a full page refresh.

- Opens in a new window.