In a recent episode of MakingChips, Hosts Jim Carr and Nick Goellner share thoughts on the state of manufacturing with industry leaders Tom Schroeder of PBC Linear and Akshat Thirani of Amper. In this conversation, they discuss several topics related to automation and process upgrades, including the business impacts from machine monitoring with Amper.

As an effect of the pandemic and labor crisis, PBC Linear had already started adding cobot technology and other automation tools like the innovative Cobot Feeder (pictured below), introduced from our brand Applied Cobotics. In 2021, these investments quickly bore their fruit, with our factory growing by 33% while only adding 3% to direct labor.

Newer investments include the impressive new $5.6 million Flexible Manufacturing System (FMS) from MCM. The FMS, which contains four horizontal CNC mills, a 90-pallet change system, and over 1500 tooling options, will be a 20-year asset for PBC Linear. This new system, alongside cobots, augmented reality training, and 3D printing are helping to lay the foundation for our two-fold increase in productivity.

Setting the Stage for Growth

PBC Linear has set an ambitious goal of doubling the size of the business over the next five years. This means streamlining existing processes and overcoming obstacles through additional automation investments.

Tom Schroeder, Executive Vice President of Plant Operations and Sourcing at PBC Linear, explains that one of those obstacles is the ongoing and worsening labor crisis. Today, skilled machinists are hard to find due to a variety of factors. Twenty or thirty years ago there was a large pool of workers to fill those roles. Today, the harsh reality is that pool has dried up.

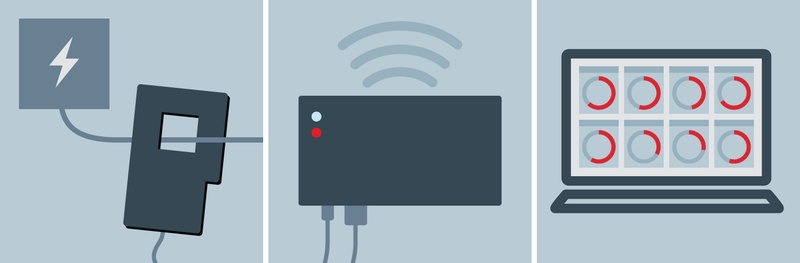

Amper works by first installing non-invasive sensors to the power supply, then connecting to cellular or Wi-Fi Gateway for system calibration. Once set up, users are able to access operational analytics from any device.