Design options to meet your needs

Flanged Ball Nut

Best used when:

You have room for a wider mounting surface and want straightforward bolt-on installation.

Key benefits:

- Easy to mount with bolt holes in flange

- Strong, secure attachment

- Great for general-purpose industrial designs

Cylindrical Ball Nut (Externally Threaded)*

Best used when:

Space is tight and you want the nut to thread directly into a housing.

Key benefits:

- Compact, space-saving design

- Clean, round outer profile

- Ideal for cartridge-style or enclosed assemblies

- Simplifies integration into cylindrical housings

Cylindrical Ball Nut (No External Threads)

Best used when:

You need a custom mounting solution or clamp-style housing.

Key benefits:

- Maximum design flexibility

- Works well in split housings or clamping blocks

- Good for custom or highly integrated assemblies

Benefits of Ball Screws

Roll with Confidence

Our miniature metric ball screw product line is currently offered in diameter sizes of 6 mm, 8 mm, and 10 mm, with options for lead length and nut type. Depending on the application, each nut can be acquired in either a flanged or cylindrical configuration.

Dynamic load ratings are an important factor when determining the correct miniature ball screw for an application. PBC Linear will provide conservative dynamic load rating values within this product family, based on 1,000,000 Rev (N). This ensures trusted, reliable performance for those looking to implement miniature ball screws into their systems.

Preload Option -- Ball screws from PBC Linear come standard without preload (backlash clearance held to 0.05 mm MAX). Contact a PBC Linear Application Engineer about reduced backlash options.

Motors – Customers looking for a complete ball screw package can count on PBC Linear for the most appropriate world-class NEMA stepper motors to offer precise positioning and speed control.

Journaling -- Custom journaling of the screw ends and additional support blocks can be requested for unique customer requirements.

6 mm x 1 mm

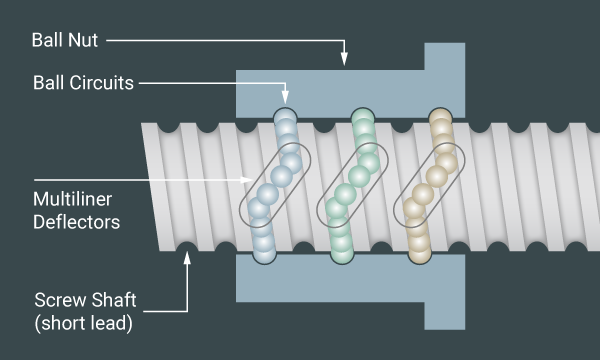

Internal Multi-liner

6 mm x 2 mm

Internal Multi-liner

8 mm x 1 mm

Internal Multi-liner

8 mm x 2 mm

Internal Multi-liner

8 mm x 2.5 mm

Internal Multi-liner

10 mm x 2 mm

Internal Multi-liner

Ball Screws vs Lead Screws

Choosing the correct screw-driven technology

Lead Screw Advantages:

Ball Screw Advantages:

What is the lifetime of Ball Screws?

The formula to calculate the service life that 90% of identical, properly lubricated ball screws are expected to reach is:

Where:

L10 = service life (revolutions)

Ca = dynamic load rating (N)

Fm = average axial load (N)

Where:

Lh = service life (hours)

nm = average rotational speed (rpm)

In applications where vibration or impact loading is present, the life calculations can be adjusted as follows:

| Vibration or Impact | (fw) Factor |

|---|---|

| Minor | 1.0 to 1.2 |

| Low | 1.2 to 1.5 |

| Moderate | 1.5 to 2.0 |

| High | 2.0 to 3.5 |

I. Average Axial Load Fm for Constant Rotational Speed and Varying Axial Load

Where:

F1,2,...n = load per cycle unit (N)

p1,2,...n = cycles (%)

II. Average Rotational Speed nm at Constant Axial Load

Where:

n1,2,...n = rotational speed per cycle unit (rpm)

p1,2,...n = cycles (%)

III. Average Axial Force and Rotational Speed

When the axial load and the rotational speed vary between different values:

Ball Screws when you need them

- Choosing a selection results in a full page refresh.

- Opens in a new window.