Components:

Retrofit or OEM:

Industries:

Problem:

Solution:

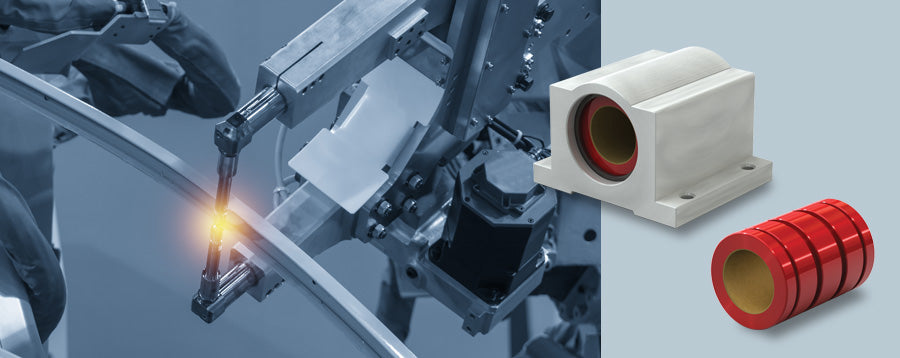

The maintenance-free plain linear bearing solution

Simplicity plain linear bearings, pillow blocks, and nonhardened shafting were specified for the new slide design for multiple factors. The pillow block’s aluminum shell reduced the overall weight of the slide system. The bearings outperformed the linear ball bearing competitors by tolerating higher shock loads and temperatures. The welding spatter and other environmental hazards were kept out of the bearing by tough molythane seals.

Results / ROI

The customer is pleased with the Simplicity® bearing’s higher performance and reduction in weight. Shock loading, temperature extremes, and contamination did not adversely affect bearing life. The result has been the low-cost implementation of thousands of bearings into slide systems that are now smooth, quiet, and reliable.