Components:

Retrofit or OEM:

Industries:

Problem:

Solution:

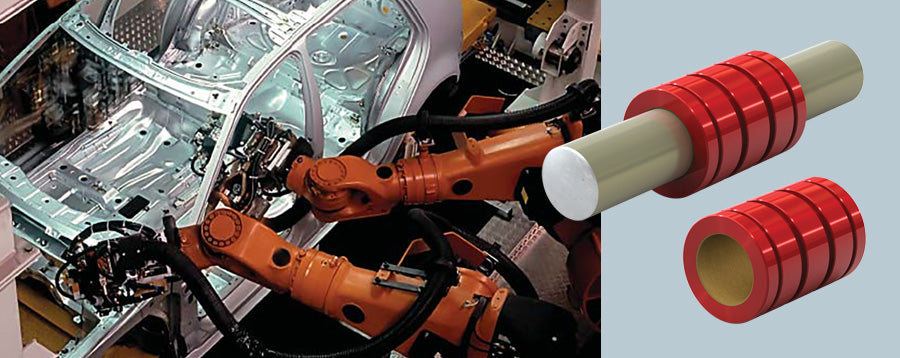

The PBC Linear maintenance-free bearing solution

Simplicity® self-lubricating plain linear bearings and pillow blocks were recommended for the new slide design. The lightweight aluminum shell reduced overall weight, and the PBC Linear bearings also outperformed the linear ball bearing competitors. Shock loads and high temperatures were tolerated, and the sand was kept out of the bearing by tough molythane seals. The results were, and continue to be, a smooth, quiet operation. Backed by the patented FrelonGold® liner from PBC Linear, the Simplicity bearing is designed to last in the worst possible environments with minimal lubrication and maintenance.

Results and application details

Customer is pleased with the performance and weight reduction gained by using Simplicity bearings. Shock loading, temperature extremes and tremendous contamination do not prevent Simplicity from providing long trouble-free bearing life. This is a great improvement over the ball bearings that were the cause of unplanned downtime and dramatically increased production costs.

Simplicity bearing liners can handle loads up to 20x that of the competing linear ball bearing systems while increasing speed capabilities by 50%. Their corrosion resistance can handle temperatures ranging from -400° F to +400° F, and are virtually impervious to shock vibration. With no moving parts to stall, Simplicity bearings will NOT catastrophically fail!

Simplicity technology is a perfect fit in the automotive industry. Testing, product feeding conveyors, assembly lines, wash down machines, painting lines, welding applications and die storage are all examples of specific applications where Simplicity technology has been installed with success.

Discover the best bearing solution for your linear bearing application:

- Find more information on Closed Linear Plain Bearings and Plain Linear Bearing Pillow Blocks

- Request your FREE product sample

- Request a quote

-

Contact an engineer

Browse all linear bearings from PBC Linear