Why use a cartesian linear actuator format?

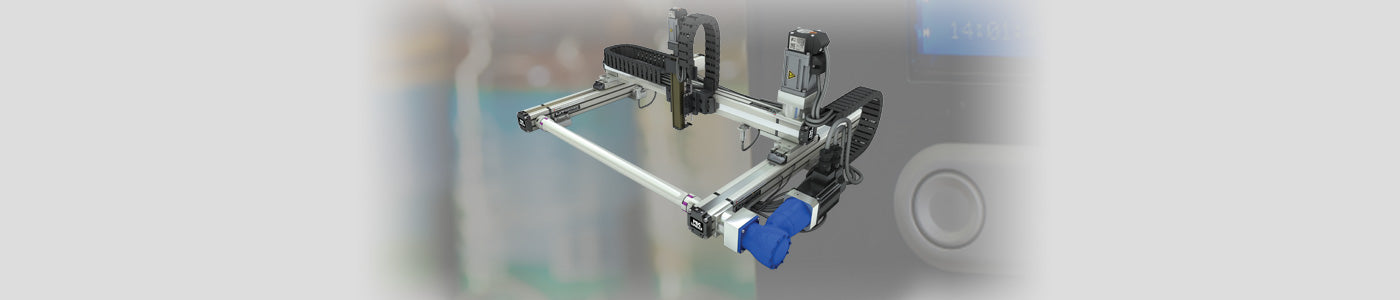

Cartesian robots, equipped with linear actuators, excel in a multitude of applications due to their high-speed travel, precise multi-axial guidance, wide working envelope, and versatility, including packaging, dispensing, palletizing, and large-scale assembly. They can be designed as center-stacked assemblies for low-cost, high-speed linear guidance, and utilize linear actuators for cantilevered motion in precision pick-and-place applications. Additionally, Cartesian robots can function as gantries, accomplishing tasks through overhead manipulation, which frees up floor space and simplifies the assembly line. High-performance positioners, including linear actuators along each axis, support the gantry’s wide maneuverability across the working envelope. Cartesian multi-axial gantries can precisely lift heavy loads along a broad working space for repeatable operation and sophisticated automation.

An emerging trend in robotics that gives Cartesian systems an edge is the simplification of controllers. Typically, each robot along an assembly line would have its own unique control system, along with a master controller for the overall line. Each robot controller comes with its own software, manuals, and technical guides, necessitating further machine training and increasing maintenance costs. Cartesian assemblies, with their wide working envelope, reduce and simplify control needs. Fewer controllers lead to less periodic maintenance and training, streamlining the automation process, simplifying system components, and saving costs.

Cartesian robotics in automated retail

Automated retail and vending is one area where cartesian robots are becoming mainstream. This year, $775 billion will be spent on adding new kiosks world wide! That is quite an expansion for a market that used to be reserved to candy bars and gum. Now, designers are employing more sophisticated techniques to ensure reliable retrieval and delivery for higher value items; such as MP3 players, DVD's and even prescriptions. As expected, motion control and positioning have a great effect on the cost, durability and life of the kiosk.

How to Design a Kiosk for Unattended Retail

Find out more about designing retail kiosks using Cartesian systems with linear actuators by downloading our White Paper: How to Design a Kiosk for Unattended Retail. Designers, engineers, and builders of these kiosk and handling systems put a large amount of focus and energy into the front-end interface. In this white paper, PBC Linear explains key items that will help a project and design team when selecting the components for product delivery systems.

![]() Contents includes parameters for various retail applications, three basic types of mechanical retrieval and delivery systems, factors contributing to “accuracy” and “repeatability,” and the tribological comparison of linear motion components. All of these areas help to determine the components and conditions under which the project will be completed. Also included are the factors surrounding the choice of mechanics to determine the correct configuration, and charts that apply the “I”, “H”, and carousel gantry formats to the X, Y, and Z axis.

Contents includes parameters for various retail applications, three basic types of mechanical retrieval and delivery systems, factors contributing to “accuracy” and “repeatability,” and the tribological comparison of linear motion components. All of these areas help to determine the components and conditions under which the project will be completed. Also included are the factors surrounding the choice of mechanics to determine the correct configuration, and charts that apply the “I”, “H”, and carousel gantry formats to the X, Y, and Z axis.

This white paper examines vital areas for designers and engineers to consider when developing new unattended kiosks. It is a helpful guide that gives real-world applicable examples of where certain products have the greatest impact, and gives warnings and recommendations regarding the use of specific products, such as our line of linear actuators, in applications.

Additional related content and downloads:

- To see more on Kiosks for unattended retail, download our Cartesian Robotic Delivery Systems brochure.

- For more information on mechatronic solutions in Cartesian robots, read the Linear Actuators in Cartesian Robot Assemblies blog

- To see more information on mechatronics from PBC Linear, download the Linear Actuators and Mechatronic Enabled Systems Catalog