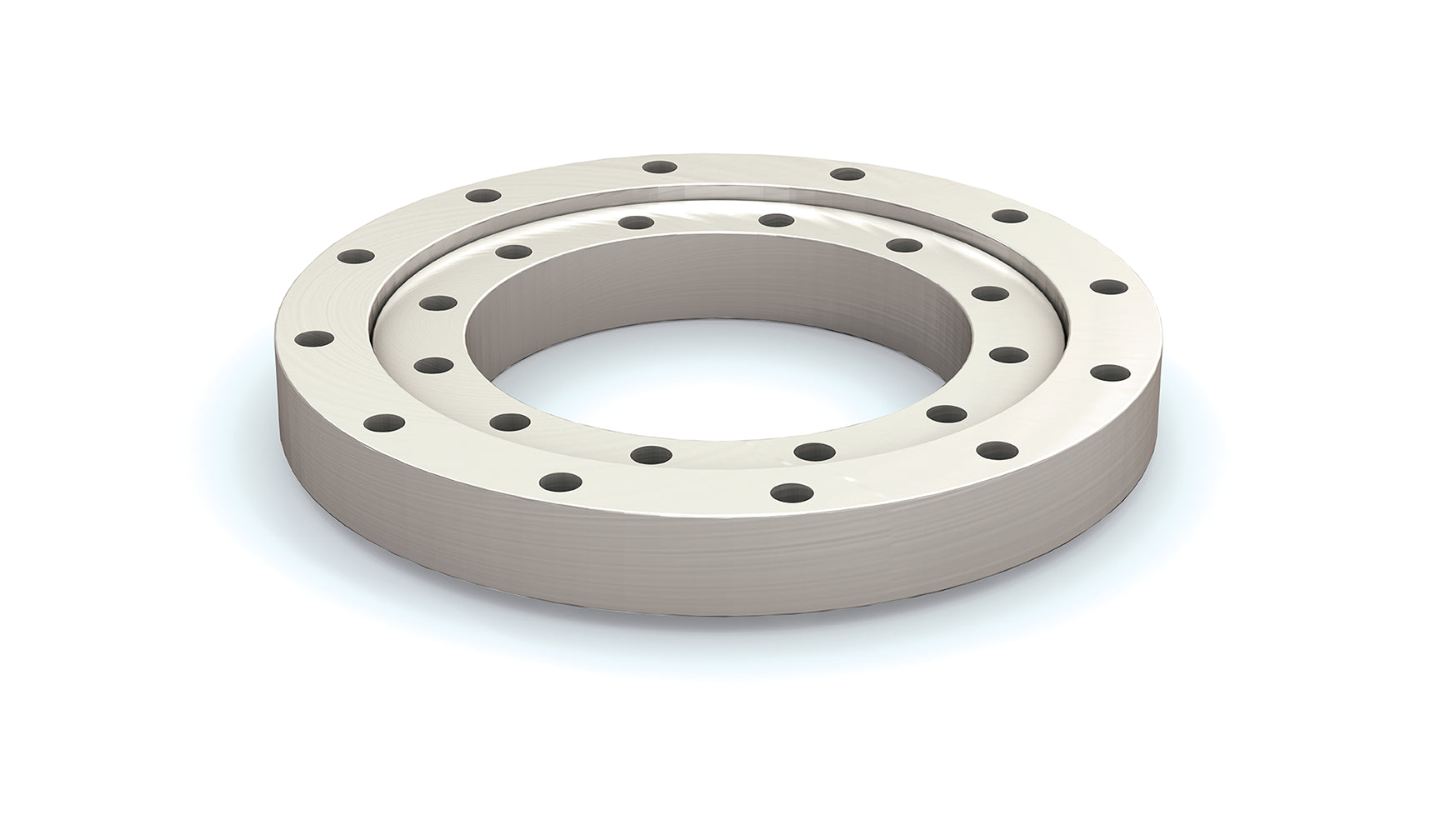

1. Inner Ring & 2. Outer Rings

The bearing comprises an inner and outer ring made of medium carbon steel. Each ring features at least one precision raceway designed to transfer loads and relative motion between different equipment structures.

3. Rolling Elements

Hardened chrome alloy steel balls act as the rolling elements, facilitating relative rotation and load transmission between the inner and outer rings.

4. Spacers

Plastic spacers separate the rolling elements and are engineered to reduce friction, skidding, and jamming during rotation.

5. Mounting Holes

Slewing ring bearings have uniformly spaced through holes. If a special bolt pattern or tapped hole is required, contact our application engineers.

6. Seals

Each side of the slewing ring bearings is equipped with an elastomer seal to retain lubricant and protect the bearing from dust and small particle contamination.

7. Grease Fitting

A grease fitting is provided in one of the bearing rings for periodic lubrication of the raceway and internal components, with larger bearings having more fittings.