Components:

Retrofit or OEM:

Problem:

Solution:

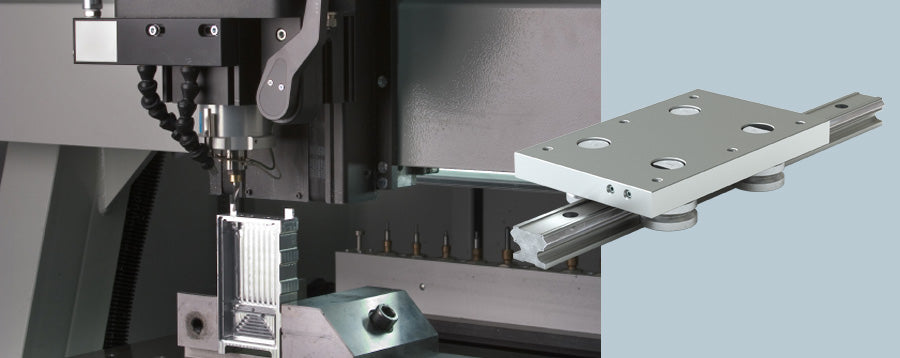

V-Roller Linear Guides from PBC Linear enhance the precision of CNC routers through Integral-V Technology (IVT), delivering a streamlined, high-accuracy linear motion solution. IVT’s v-wheels and v-rails simplify traditional linear guide systems, providing cost-effective, reliable routing for industries such as woodworking, metalworking, and foam cutting. By combining lightweight aluminum extrusions with precision-machined v-rails, IVT ensures smooth, low-friction motion, reducing installation time and production costs while achieving tight tolerances across large work areas.

IVT’s V-Roller Guides utilize v-wheels that glide seamlessly along v-rails, eliminating the need for complex alignment processes found in conventional linear guides. These durable v-wheels support high-speed spindles exceeding 20,000 RPM, enabling precise cuts without compromising accuracy. PBC Linear’s proprietary SIMO process machines v-rails with synchronized tooling, ensuring superior parallelism and flatness essential for sub-micron precision in CNC routing applications.

Results/ROI

Recently, IVT has been implemented in several different routers spanning a wide variety of industries. Using custom-built extrusions, IVT has drastically reduced the router’s mounting components, installation time, and production cost; yielding a simplified, highly accurate linear motion guide. With IVT’s custom integrated frame design, the lightweight aluminum structure can hold up against immense weight and provide highly accurate, long-lasting travel for the router. From installation to the end result, IVT creates a simplified and economical solution to linear motion in routing systems.

Discover the best bearing solution for your application

- Browse and Buy V-Roller Guide Integral-V Technology (IVT)

- Browse and Buy Linear Guides from the Entire Collection

- Request your FREE product sample

- Request a quote

- Contact an engineer