Components:

Retrofit or OEM:

Problem:

Solution:

The PBC Linear Solution

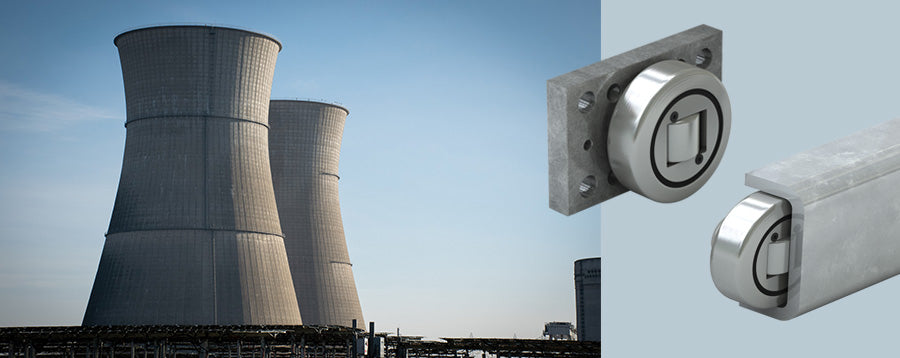

To solve the problem a company called Quality Engineered Products turned to Hevi-Rail®, the cam roller technology with a strong reputation for long-lasting linear motion in the toughest of environments. Utilizing Hevi-Rail, Quality Engineered Products designed a rotating “lazy susan” system for nuclear reactor vessel stud racks. About 42" in diameter, the new circular stud rack could be hand-rotated to facilitate easy loading from the crane. Hevi-Rail® works to promote an even dispersion of loads and forces being acted upon it. Machined into a circular rail, the hardened steel rail and bearings had no problem tolerating the total weight of 9 reactor studs! The Hevi-Rail bearing’s innovative linear and axial bearings also allowed for a smooth rotating motion that immediately pleased the maintenance crew due to the new-found ease in their job.

Results / ROI

Thanks to the ingenuity of Quality Engineered Products and the long-lasting heavy-duty performance of Hevi-Rail, the maintenance crew no longer needed to waste time re-positioning the stud rack under the crane in order to proceed with the loading process. The time saved is doubled as the entire process is performed in reverse during reactor re-assembly after refueling.

Discover the best bearing solution for your application

- Find more information on Hevi-Rail

- Request your FREE product sample

- Request a quote

- Contact an engineer