Components:

Retrofit or OEM:

Problem:

Solution:

The PBC Linear solution

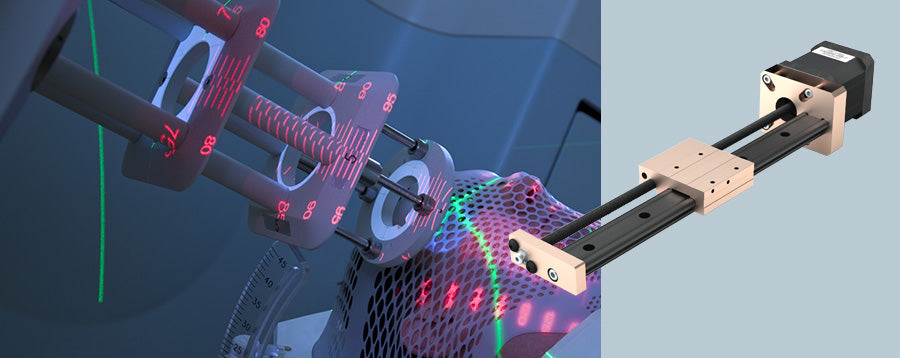

PBC Linear was approached in order to bring a compatible substitute to the motion control assembly that consisted of 33 components including multiple complex machined pieces. Also, the machining and assembly processes was being completed by several separate vendors, resulting in a slower time to market. The PBC Linear team was resolved to streamline this process through the use of a single-piece, plain bearing assembly to simplify installation, improve reliability, and reduce the total installed cost.

The lead screw driven Mini-Rail® linear stage from PBC Linear was the recommended solution. Mini-Rail linear actuators use proven Simplicity® plain bearing technology to ensure long-lasting, maintenance-free travel. Its 303 stainless steel lead screw provided the optimum drive for accuracy and subtle adjustment. With this application, custom brackets were installed into the application for optimized fit. All of these advantages combined to create a Mini-Rail linear stage solution that offered the compact positioning the design team was searching for.

Results / ROI

During testing, the design team saw an immediate savings in both time and cost, not to mention an improvement in reliability. The custom Mini-rail solution from PBC Linear reduced the total installed cost by 40-percent. Also, since PBC Linear does their machining in-house, the new solution streamlined processing and simplified machining vendors down to one.

Discover the best linear motion system for your application:

- Find more information on our Mini-Rail Linear Actuators

- Request your FREE product sample

- Request a quote

- Contact an engineer