What linear shafting materials are available?

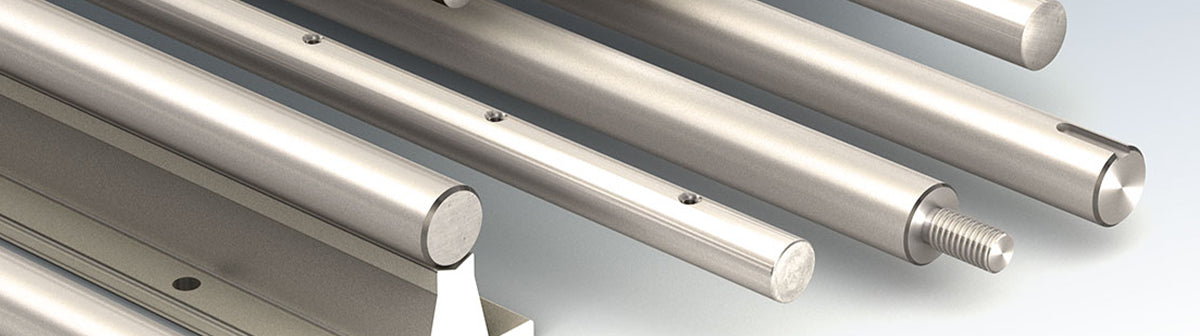

Linear shafting is available in 420 stainless steel, 440C stainless steel, 316 stainless (select diameters), 1060 steel, and ceramic coated aluminum shafting as a standard. 303/304 stainless steel and 52100 hollow shafting are available as special orders.

How are hardness gradients created in linear shafting?

Hardness gradients in linear shafting, like 440C stainless steel and 1060 steel, are achieved through induction heat treatment. This process hardens the outer surface while keeping the inner core softer, enhancing durability and flexibility. For 1060 steel, standard tolerances ensure a minimum hardness of 60 HRC with a specified depth, depending on diameter; for 440C stainless, it’s 50 HRC minimum. Ceramic-coated shafting reaches 70+ HRC for superior wear resistance.

What is the difference between precision ground linear shafting and bright bar?

While similar precision ground linear shafting and bright bar appear similar they are not necessarily the same. Precision ground linear shafting is ground to very tight tolerances on diameter and surface finish with the purpose of supporting a linear plain bearing or ball bearing for linear motion. The centerless grinding process leaves a shiny or bright exterior. Bright bar can be ground to a looser or a tight tolerance. Bright bar references to the “bright” or shiny exterior. Bright bar can be used in numerous applications where aesthetics of a shiny surface is needed.

What is the difference between 420 stainless steel and 440C stainless steel?

While very similar, 420 stainless steel has a slightly lower carbon content. The lower carbon content makes it slightly softer, but it increases the machinability of the material. 440C has a high carbon content that allows for a harder finish after heat treating and slightly more corrosion resistance than 420 stainless steel. However, this hardness also makes it more difficult for machinability. Many steel mills are moving away from producing 440C as the higher carbon content makes it harder to produce, more expensive, and less environmentally friendly than 420 stainless steel.

I am really not sure what type of shaft I need for my application. Can you help me?

Yes! We would be happy to assist you. You can use our online configurator (Customize To Order PBC LINEAR Linear Motion Products) to specify exactly what you want, or simply call +1.815.389.5600 to speak to an Inside Sales Representative. For more technical questions, call +1.815.389.5600 to ask for an Application Engineer to assist you with your application requirements.

Can linear shafting handle side loads?

While linear shafting can handle some side loading depending on the diameter and material, it is primarily designed for axial load applications. If your application is likely to see side loading, you may want to consider using the aluminum support rail or steel low profile support rail from PBC Linear to increase the rigidity of the system.

What are the top three things to remember when designing a system with linear shafting?

Load Capacity and Support

You need to know the total weight that the system will see during static and dynamic loading. The weight is crucial for selecting the correct diameter and supports to minimize deflection of the shaft underweight. Too much deflection can lead to premature wear of the shaft or the bearings.

Alignment and Tolerances

Alignment is crucial in a linear shafting and bearing system. If you have two linear shafts in parallel, even a few extra thousandths of an inch over a distance can be the difference between smooth linear motion and binding. Tolerances are also critical when selecting the shaft and bearing. An oversized shaft, class N, with a linear ball bearing can create preload increasing the rigidity; however, the downsides are potentially creating premature wear on the shaft or bearing and increasing the force needed for axial movement due to the preload.

Bearing Selection and Compatibility

Selecting the right bearing is crucial for the performance of your application. For example, linear ball bearings work best on 1060 shafting and 440C shafting; they do not work well on 300 series stainless steel or ceramic-coated aluminum. Simplicity linear plain bearings with Frelon Gold liner work with 1060 and ceramic-coated aluminum. Simplicity linear plain bearings with Frelon J liner work best on ceramic-coated aluminum shafting and 300 series stainless steel shafting. Frelon W liner is an FDA-compliant bearing liner that can be combined with a stainless steel body for washdown and food contact applications.

Do you offer 1566 steel linear shafting?

Does PBC Linear offer hollow round shafting?

For Simplicity 60 Plus shafting, can you provide a certification showing the exact depth of my case hardness for each shaft ordered?

How are the load ratings for SRA aluminum support rails calculated?

Is Simplicity 60 Plus 440 stainless steel shafting magnetic?

I was asked to supply the “Y” dimension when ordering my length product – what does that mean?

What are the approximate yield and tensile strength estimates for PBC Linear Case 60 Plus C1060 steel shafting?

| Case | Core | |

|---|---|---|

| Tensile | 335,000 psi | 100,000 psi |

| Yield | 250,000 psi | 75,000 psi |

Note: Case hardness depth will vary by shaft diameter. Minimum case hardness depths specified on page 45 for inch series and page 82 for metric series in the RST (Round Shaft Technology) Catalog.

What are the approximate yield and tensile strength estimates for PBC Linear Case 50 Plus 440C stainless steel shafting?

| Case | Core | |

|---|---|---|

| Tensile | 341,500 psi | 113,805 psi |

| Yield | 182,750 psi | 60,900 psi |

Note: Case hardness depth will vary by shaft diameter. Minimum case hardness depths specified on page 45 for inch series and page 82 for metric series in the RST (Round Shaft Technology) Catalog.