This year, PBC Linear marks 40 years of engineering linear motion solutions. This has been achieved through a range of precision engineered components and mechatronics delivered from a centralized United States manufacturing facility. As we celebrate this milestone, PBC Linear is in the process of rolling out new products and making substantial investments for continued growth.

The story of PBC Linear begins with an innovative solution and patent to the common problem of failing linear ball bearings. Forty years later, that successful bearing design is now part of a larger family of inventive products and services related to linear motion technologies. Our full scope of product categories has expanded to include linear bearings and rails, patented linear guide systems, linear actuator technology, and our own specially designed SIMO® extrusion process.

More recently, our new Applied Cobotics brand has introduced the Cobot Feeder which offers customers a collaborative automation tool for lights-out manufacturing. As our manufacturing facility grows and evolves, we continue to provide expanding markets with effective products and services, and in turn reinforce the PBC Linear brand as a trusted source for linear motion technologies.

PBC Linear provides emerging industries and demanding applications with innovative solutions in linear motion products and services. This is achieved through a range of precision engineered components and mechatronics delivered from a centralized United States manufacturing facility.

The story of PBC Linear begins with an innovative solution and patent to the common problem of failing linear ball bearings. Forty years later, that successful bearing design is now part of a larger family of inventive products and services related to linear motion technologies. Our full scope of product categories has expanded to include linear bearings and rails, patented linear guide systems, linear actuator technology, and our own specially designed SIMO® extrusion process.

More recently, our new Applied Cobotics brand has introduced the Cobot Feeder, which offers customers a collaborative automation tool for lights-out manufacturing. As our manufacturing facility grows and evolves, we continue to provide expanding markets with effective products and services, and in turn reinforce the PBC Linear brand as a trusted source for linear motion technologies.

PBC Linear is headquartered just west of Chicago in the rejuvenated manufacturing city of Rockford, Illinois. The company designs and manufactures many of their products here, providing an economic engine to the region. The company’s culture is a blend of midwestern work ethic paired with skilled technicians, knowledgeable service personnel, and a multi-disciplined group of trained engineers – not to mention a dog-friendly office. Together, they form a full-service team that creates long-lasting and cost-efficient linear motion solutions for a variety of worldwide industries.

Through the years, industry professionals have learned to count on tried and true product lines from PBC Linear. This solid foundation of brands includes Redi-Rail®, which utilizes lightweight structural components and high-speed self-lubricated roller bearings; and Hevi-Rail®, whose heavy-duty linear bearing systems provide high load capacity and simple installation.

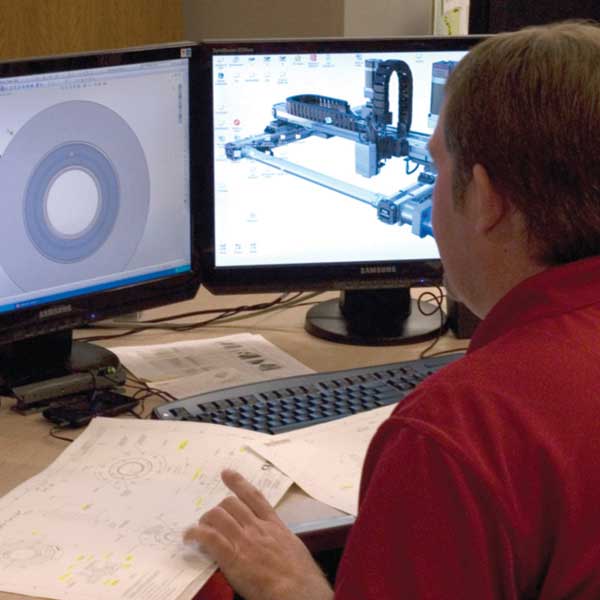

PBC Linear continues to evolve in order to meet customer demands. In 2008, the company introduced its newly developed and patented Integral V™ Technology (IVT). This innovative linear guide system eliminates unnecessary components, while maintaining high precision and reducing cost. That same year, PBC Linear unveiled its new complete line of Linear Actuator Technology (LAT). This technology has been applied in many different industries and is another way that customers can benefit from lower production times and costs.

In addition to new products, PBC Linear has designed and patented the SIMO® Machine (Simultaneous Integral Milling Operation). The new process brings a much higher degree of precision to the aluminum extrusion process. The result for customers is a more accurate product, produced in minutes instead of hours, and without extra costs.

To learn more about the broad range of the toughest, smoothest and quietest linear and rotary bearings and systems available, please contact a PBC Linear representative today! See our complete, full-service list of engineering capabilities and manufacturing capabilities.